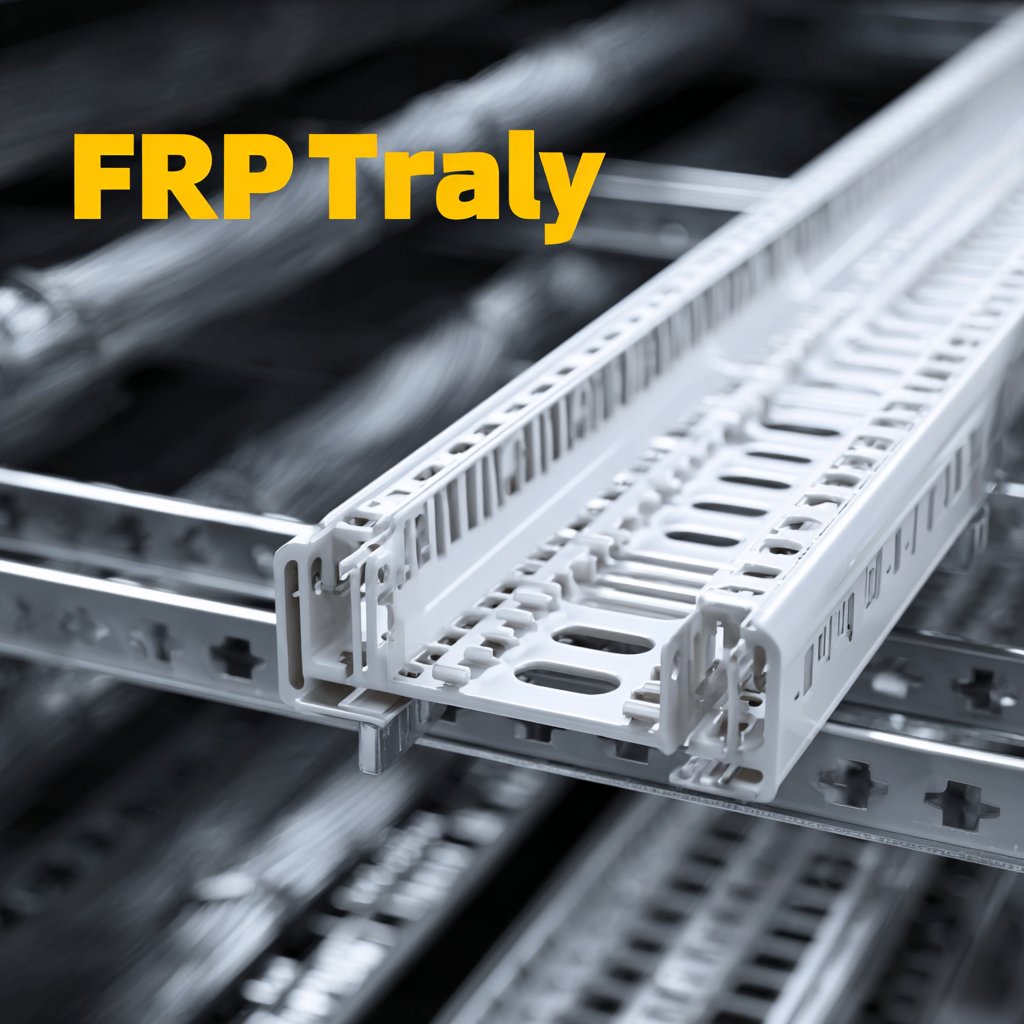

When embarking on a project that requires effective cable management solutions, the choice of materials becomes crucial to ensure durability and efficiency. In this ultimate guide, we will delve into the ins and outs of selecting the best FRP (Fiberglass Reinforced Plastic) Cable Tray for your specific needs.

FRP Cable Trays are becoming increasingly popular due to their lightweight, corrosion-resistant, and high-strength properties, making them an ideal choice for various industries. However, with a plethora of options available in the market, knowing what factors to consider can be overwhelming.

This comprehensive guide aims to equip you with the knowledge and insights needed to make an informed decision, ensuring the optimal performance and longevity of your cable management systems. Let's explore the key elements that will help you navigate the process of choosing the perfect FRP Cable Tray for your project.

When selecting FRP (Fiber Reinforced Polymer) cable trays for industrial applications, several key considerations must be taken into account to ensure optimal performance and longevity. One of the primary factors is the environmental conditions the trays will be subjected to. According to a report by MarketsandMarkets, the global FRP composite materials market is expected to grow at a CAGR of 6.5% from 2023 to 2028, largely driven by the demand in challenging environments such as chemical processing plants and offshore facilities. This growth underscores the importance of choosing FRP for its resistance to corrosion and its lightweight properties, which significantly reduce installation and maintenance costs.

Another crucial consideration is the load-bearing capacity of the cable trays. Industry standards, such as those put forth by the National Electrical Manufacturers Association (NEMA), highlight the importance of adhering to specific load requirements to avoid infrastructure damage. A critical analysis by Grand View Research indicates that improper selection can lead to equipment failures costing companies thousands of dollars. Therefore, it is vital to assess the tray configuration, including width, height, and the potential weight of cables, to ensure that the chosen FRP cable tray can adequately support the installation over its lifespan.

| Dimension | Value | Material Type | Load Capacity | Installation Method |

|---|---|---|---|---|

| Width | 300 mm | Pultruded FRP | 1000 kg/m | Bolt on |

| Height | 50 mm | Sheet Molding Compound | 800 kg/m | Welded |

| Length | 2000 mm | Vinyl Ester | 600 kg/m | Hanging |

| Coating | Urethane | Pultruded FRP | 750 kg/m | Cable tray accessories |

When it comes to selecting the right cable tray for your project, opting for Fiberglass Reinforced Plastic (FRP) offers significant advantages over traditional metal options. FRP cable trays are renowned for their excellent corrosion resistance, making them ideal for environments prone to chemical exposure. According to the National Association of Electrical Distributors (NAED), corrosion-related failures account for nearly 30% of maintenance costs in electrical installations. By choosing FRP, these costs can be mitigated substantially since the material does not rust or degrade in harsh conditions.

Additionally, FRP cable trays boast a lightweight design, which facilitates easier transport and installation. Reports from the Electrical Contractor (EC) indicate that using lighter materials can reduce installation time by up to 50%, translating into significant labor cost savings. Moreover, FRP is inherently non-conductive, providing enhanced safety in electrical applications. In fact, industry studies show that non-conductive materials can diminish the risk of electrical hazards by 40%, making FRP an optimal choice for both efficiency and safety in today’s infrastructure projects.

When selecting FRP cable trays for your project, understanding their load capacity and durability in harsh environments is essential. FRP, or fiberglass-reinforced plastic, offers excellent strength-to-weight ratios, making it ideal for industrial applications where weight is a concern. Assess the specific load requirements of your installation to ensure that the chosen tray can withstand the heaviest cables without sagging, which can lead to potential damage over time.

**Tip:** Always consult the manufacturer's load rating specifications and consider a buffer to accommodate unexpected increases in weight. This foresight can prevent costly downtimes and maintenance.

Additionally, the environment plays a crucial role in the lifespan of FRP cable trays. Exposed to harsh chemicals, extreme temperatures, or high humidity, the material's integrity can be compromised. It is vital to choose FRP that is specifically designed for such conditions, often with added corrosion resistance or UV inhibitors.

**Tip:** Conduct a thorough site evaluation and match the tray's specifications to the environmental factors you expect. Investing in high-quality FRP cable trays tailored for your conditions will maximize durability and minimize replacement costs in the long run.

When choosing FRP cable trays for your project, understanding the regulatory standards and certifications is crucial, especially in global markets. These standards ensure that the materials used are safe, reliable, and environmentally compliant. In many regions, compliance with international standards can also enhance the marketability of your project. For instance, look for certifications such as ISO and ASTM, which serve as benchmarks for quality and performance.

Tips: Always verify that the FRP cable trays meet local and international safety standards. Additionally, consult with suppliers about the specific certifications their products hold, as this can affect the overall performance and longevity of your installation.

As the global FRP market grows—with estimates indicating a rise in related markets such as the basalt fiber reinforced polymer—being informed about certifications will help you navigate potential pitfalls. Opting for certified products can not only mitigate risks but also align your project with emerging market trends that favor environmentally friendly materials.

Tips: Regularly review new regulations that may affect your industry, and stay updated on technological advancements that could provide more efficient and sustainable options for cable management solutions.

When evaluating the cost-effectiveness of FRP (Fiber Reinforced Plastic) cable trays compared to traditional materials, it is essential to consider long-term savings associated with maintenance and durability. According to industry reports, FRP cable trays often have a longer lifespan due to their corrosion resistance and lightweight properties, which can lead to reduced replacement costs over time. Additionally, FRP's non-conductive nature minimizes the risk of electrical hazards, potentially lowering insurance premiums for projects that prioritize safety.

Moreover, transitioning towards above-ground cable management systems, such as those utilized in solar infrastructure, highlights the growing trend of prioritizing sustainability and efficiency. Studies indicate that above-ground solutions can improve accessibility for maintenance and reduce the time spent managing cables, ultimately leading to enhanced project timelines and reduced labor costs. The investment in FRP cable trays not only supports these trends but also aligns with the broader industry shift towards eco-friendly materials and practices, further emphasizing their value in both environmental and economic contexts.

TradeManager

Skype

VKontakte