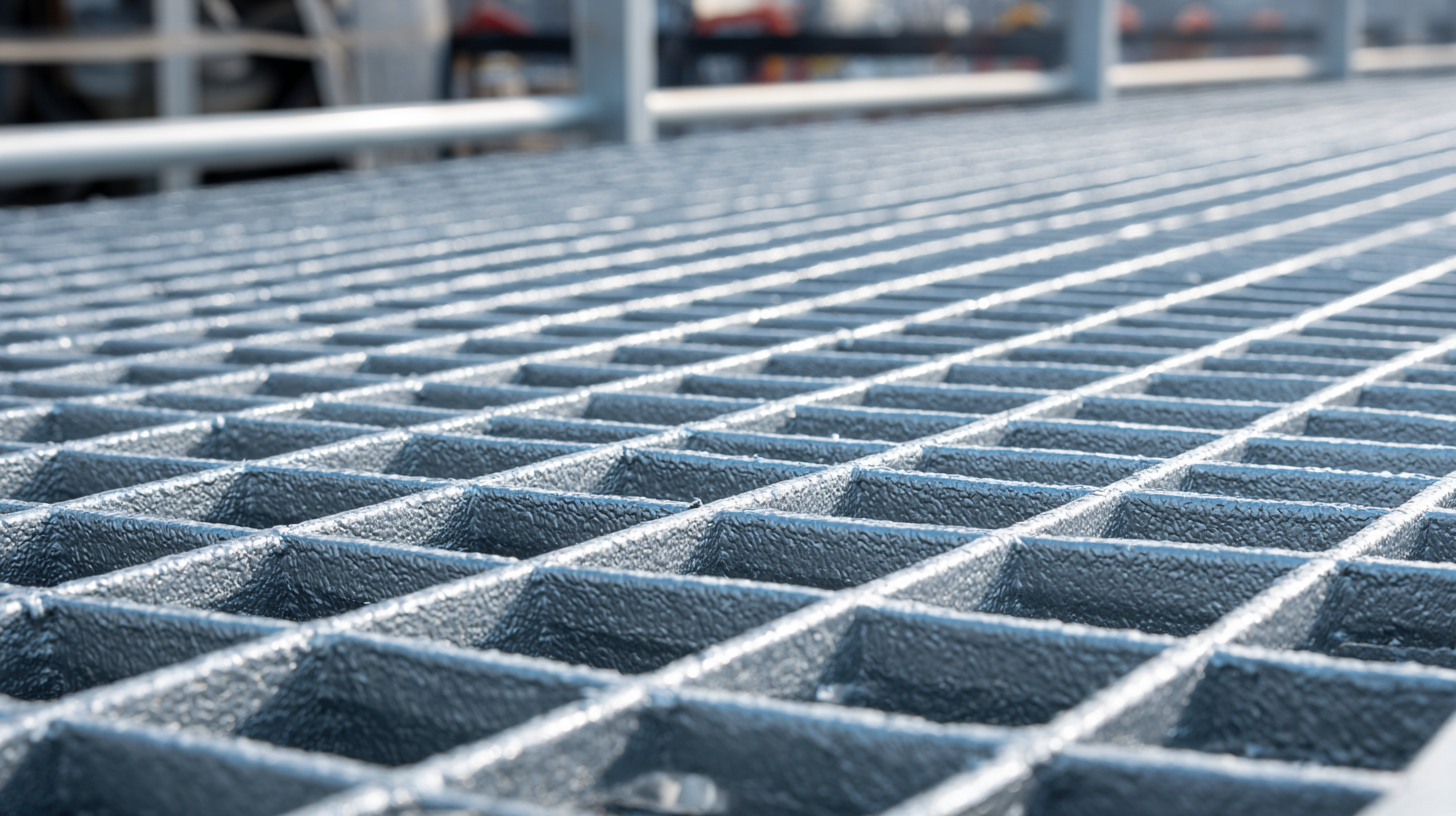

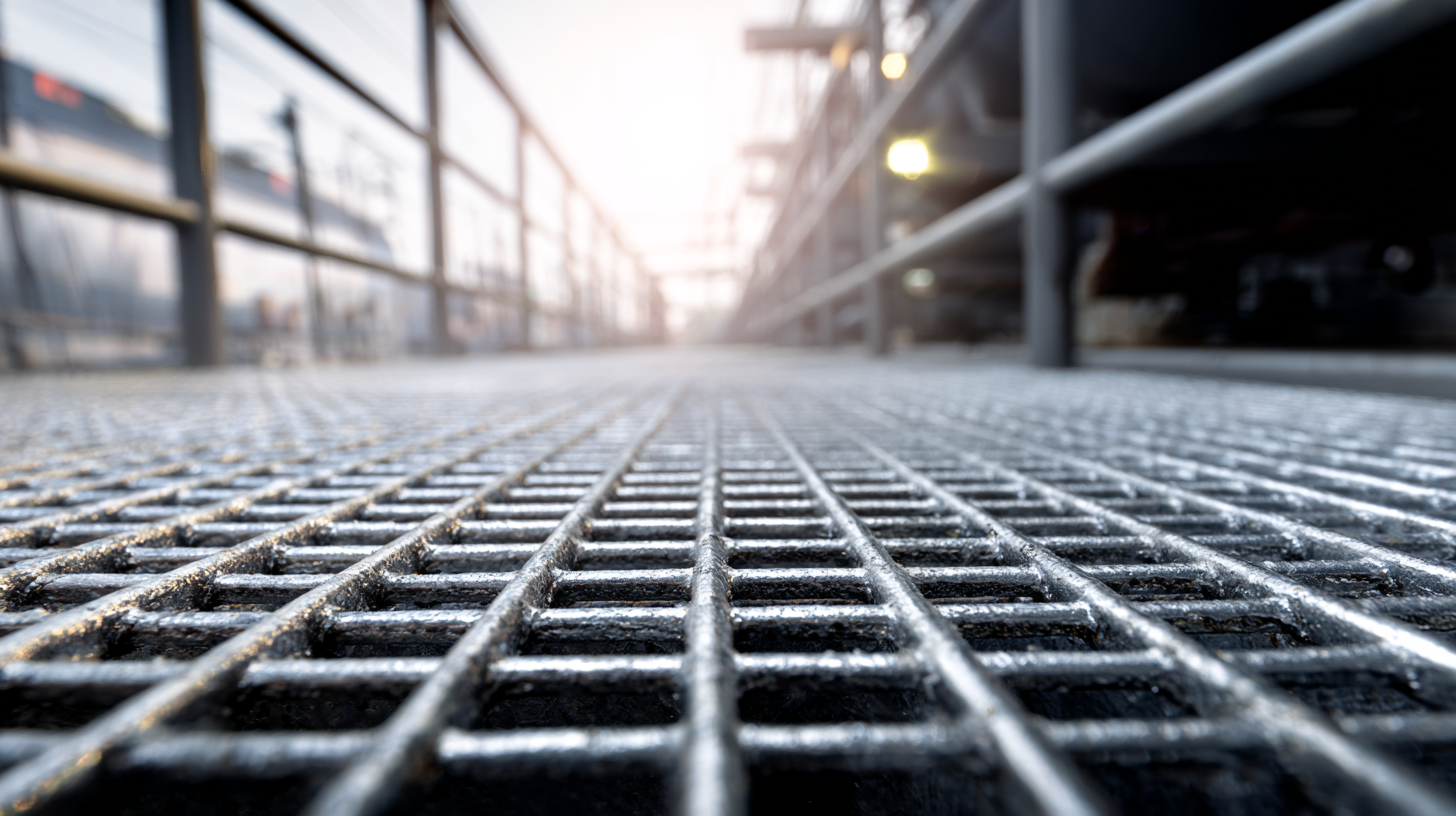

In the ever-evolving landscape of global manufacturing, Chinese firms are carving out a significant niche, especially in specialized products like FRP grating. According to a report by Allied Market Research, the global FRP grating market is projected to reach USD 1.4 billion by 2025, expanding at a compound annual growth rate (CAGR) of 4.6%. This growth trajectory highlights the increasing demand for lightweight, durable, and corrosion-resistant materials across various industries, including construction, wastewater treatment, and chemical processing. As manufacturers in China leverage advanced technologies and economies of scale, they are positioned to deliver high-quality FRP grating solutions that meet international standards and cater to the specific needs of global buyers. This blog will explore the strengths of Chinese manufacturing in this sector while also outlining the key technological trends expected to shape FRP grating production through 2025.

Chinese manufacturing has long been a cornerstone of the global supply chain, and its expertise shines brightly in the production of Fiberglass Reinforced Plastic (FRP) grating solutions. The competitive edge of Chinese manufacturers lies in their ability to combine advanced technology, cost efficiency, and scalability. With state-of-the-art production facilities and a skilled workforce, they are capable of producing high-quality FRP gratings that meet international standards, making them an attractive option for buyers across various industries.

Moreover, Chinese manufacturers are continually innovating, exploring new materials and designs that enhance the durability and aesthetic appeal of FRP grating. This commitment to innovation, paired with competitive pricing, allows them to deliver customized solutions that cater to the diverse needs of global clients. As environmental concerns grow, Chinese companies have also begun to prioritize sustainable practices, further solidifying their position as leaders in eco-friendly manufacturing. By leveraging their industry expertise and geographic advantages, Chinese manufacturers are poised to remain at the forefront of the FRP grating market, offering exceptional value to buyers worldwide.

In today's competitive global marketplace, exceptional after-sales service is crucial for enhancing customer satisfaction, particularly in the sector of FRP (Fiber Reinforced Plastic) grating. Chinese manufacturers are increasingly recognizing the importance of robust support systems that not only address customer inquiries but also ensure that clients can make the most out of their products. This commitment to after-sales service is reflected in timely responses to product issues, efficient replacement services, and comprehensive product training for users, all designed to bolster customer confidence and loyalty.

Moreover, Chinese manufacturers are leveraging technology to improve their after-sales support. Many companies now utilize digital platforms that allow for seamless communication between customers and service teams. This enables quick troubleshooting and access to resources such as user manuals and technical guides. Additionally, regular follow-ups and feedback mechanisms are put in place to troubleshoot potential issues before they escalate, showcasing a proactive approach to customer service. With these advantages, global buyers can be assured that their investment in quality FRP grating will be backed by exceptional support, leading to improved operational efficiency and long-term satisfaction.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Highly resistant to corrosion and impact. | Longer lifespan and reduced maintenance costs. |

| Customization | Available in various sizes, colors, and designs. | Tailored solutions to meet specific project requirements. |

| Lightweight | Easy to handle and install compared to metal alternatives. | Lower shipping costs and quicker installation times. |

| Safety | Non-slip surface and electrical insulation properties. | Enhanced safety for workers and reduced accident risks. |

| After-Sales Support | Comprehensive service including installation assistance. | Increased customer satisfaction and trust in product. |

When considering the overall cost-effectiveness of FRP (Fiberglass Reinforced Plastic) grating, it's essential to understand the factors that contribute to repair costs. Unlike traditional materials, FRP grating offers superior resistance to corrosion and chemical damage, which can significantly reduce maintenance expenses over time. One of the primary advantages of FRP grating is its lightweight nature, which not only simplifies installation but also minimizes potential repair costs associated with structural failures or heavy-duty usage.

Repair costs can vary based on several factors, including the extent of damage and the specific application of the grating. For example, in environments prone to harsh chemicals or extreme weather conditions, the longevity of FRP can result in considerably lower maintenance needs. Additionally, the ease of replacement for damaged panels makes FRP grating a practical choice for businesses looking to optimize their operational budgets. By investing in high-quality FRP grating, global buyers can effectively reduce long-term costs while ensuring safety and durability in their operations.

When it comes to selecting the right FRP grating supplier, buyers should prioritize key factors that align with their specific needs. First and foremost, evaluate the supplier’s reputation in the industry. Look for feedback from previous customers and assess their track record of providing high-quality products and timely delivery. A reliable supplier will offer detailed product specifications and certifications, ensuring that their FRP grating meets necessary industry standards.

Another critical aspect is the supplier’s ability to customize products. Different projects may require specific dimensions, load-bearing capacities, or resistance to environmental factors. Partnering with a supplier who is willing to understand your unique requirements and tailor their offerings accordingly can make a significant difference in the success of your project. Additionally, consider the availability of after-sales support and service. A supplier that provides thorough post-purchase support can help resolve any issues you may encounter, ensuring a smooth and efficient operational process in the long run.

When it comes to maximizing the lifespan of FRP (Fiberglass Reinforced Plastic) grating products, proper maintenance is essential. Regular cleaning is one of the key practices that can greatly enhance durability. It's important to remove dirt, debris, and any chemicals that may accumulate on the surface. Utilizing a mild detergent and water for routine cleaning will prevent the buildup of corrosive materials that can degrade the grating over time. Additionally, avoiding harsh chemicals and abrasive cleaning materials is crucial, as these can scratch or damage the surface, compromising its integrity.

Another crucial aspect of maintaining FRP grating is timely inspection and repair. Regularly check for any signs of wear, such as cracks or delamination. Early detection of these issues allows for prompt repairs, which can prevent further damage and extend the life of the materials. In regions where there is heavy foot traffic or industrial use, consider implementing a scheduled maintenance routine, which includes inspections and cleanings. By adopting these simple yet effective maintenance tips, global buyers of FRP grating can ensure that their products remain reliable and perform optimally in various applications.

TradeManager

Skype

VKontakte