In the realm of industrial applications, selecting the optimal FRP flat plate can significantly impact the efficiency and longevity of your projects. The term "FRP" refers to fiberglass reinforced plastics, known for their lightweight, durability, and resistance to corrosion, making them an excellent choice for various environments. As industries increasingly turn to innovative materials for enhanced performance, understanding how to choose the right FRP flat plate becomes crucial.

Furthermore, with China leading the charge in manufacturing and exporting high-quality FRP products, it is essential to recognize the standards and specifications that ensure reliability and effectiveness. In this blog, we will delve into the key factors to consider when choosing an FRP flat plate, ensuring you make an informed decision that aligns with your specific industrial requirements.

When selecting FRP (Fiber Reinforced Polymer) flat plates for industrial applications, several key factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the environmental conditions the plates will face. According to a report from the Global Composites Market, FRP materials excel in corrosive environments, with up to 70% less weight than traditional materials like steel, making them ideal for chemical processing industries where exposure to harsh substances is common.

Another crucial aspect is the load-bearing capacity required for specific applications. Research from ASTM International has shown that FRP flat plates can achieve tensile strengths of over 300 MPa, which is vital for industries such as construction and aerospace where structural integrity is paramount. Additionally, the thermal properties should not be overlooked; FRP materials can withstand temperatures up to 120°C without significant loss of mechanical properties, greatly expanding their range of usability across various industrial sectors. Therefore, evaluating these factors will enhance the effectiveness of FRP flat plates in meeting industrial demands.

This bar chart compares the tensile strength, corrosion resistance, and weight of various FRP flat plate materials. This information is key when selecting the appropriate FRP flat plate for your industrial application.

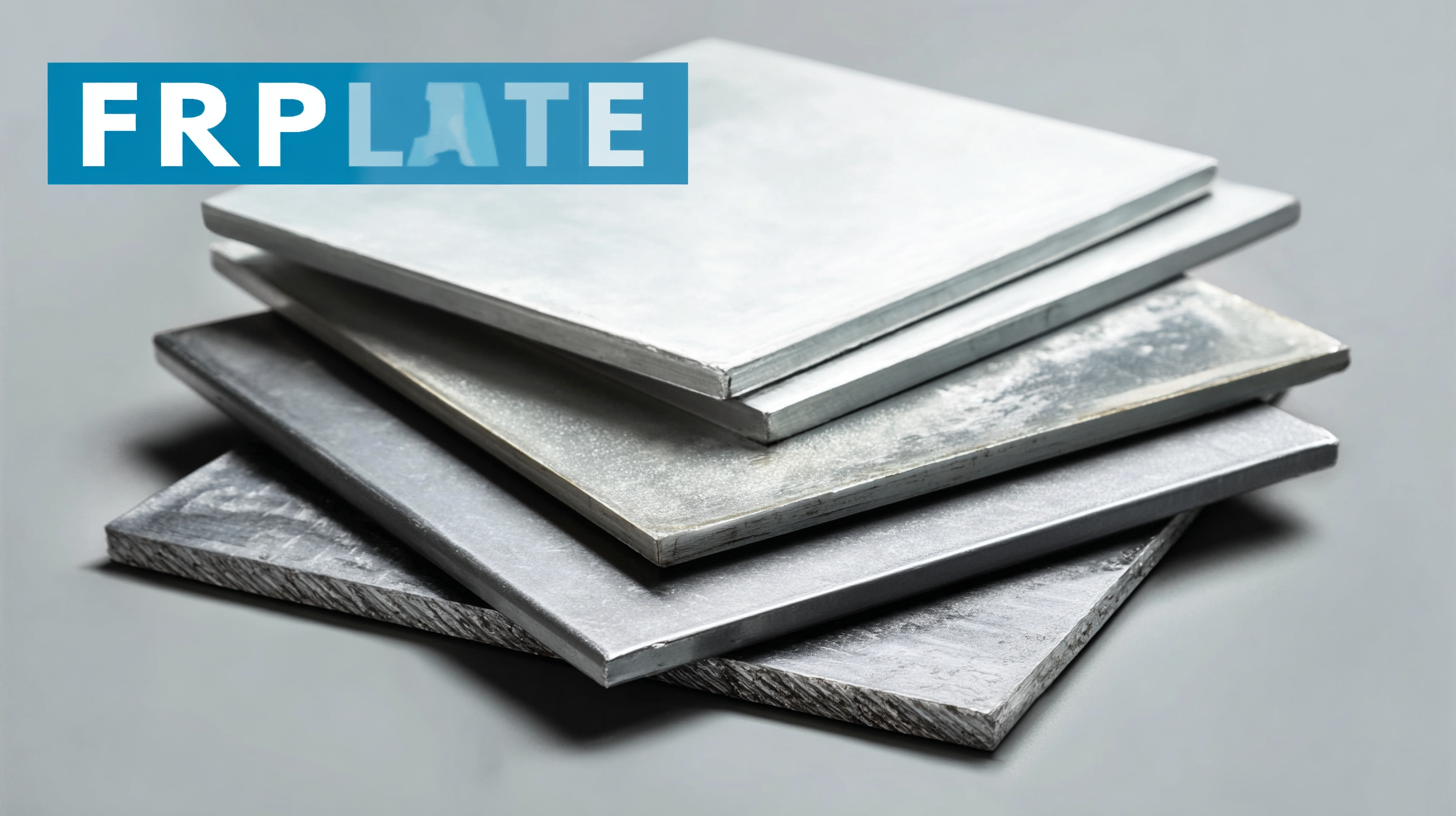

When selecting the best FRP flat plate for industrial applications, understanding the various types and properties of FRP materials is crucial. Fiber-reinforced plastic (FRP) is gaining traction across multiple sectors, including marine, construction, consumer goods, and more. According to industry reports, the global FRP market is projected to grow significantly, driven by its lightweight and corrosion-resistant qualities, making it an ideal choice for marine applications. For instance, the marine segment is expected to dominate the market with a substantial share, as FRP flat plates offer durability and performance in harsh environments.

Exploring the specific types of FRP materials, unsaturated polyester resins (UPR) are particularly notable, with applications spanning automotive carbon fiber composite parts—covering structural components, interiors, exteriors, and chassis. The automotive carbon fiber composite parts market is anticipated to exhibit robust growth, projecting a CAGR of over 12% by 2032. This increase is fueled by the rising demand for lightweight materials in passenger vehicles, commercial vehicles, and electric cars. Additionally, the versatility of resin types, including epoxy and polyester, further supports a diverse range of applications, emphasizing the critical role of material properties in selecting the right FRP flat plate for specific industrial needs.

When selecting the best FRP flat plate for your industrial application, evaluating load capacity and structural integrity is paramount. Each application presents unique demands on the materials used, making it essential to assess how the FRP plate will perform under specific load conditions. Consider the maximum load the plate will need to support, including potential dynamic loads, and ensure that the chosen FRP plate can handle these stresses without compromising safety.

Additionally, the structural integrity of the FRP flat plate is crucial. This involves examining factors such as the plate's thickness, reinforcement type, and manufacturing process. A well-engineered FRP plate should maintain its shape and resistance against environmental factors such as moisture and chemicals. Testing for compliance with industry standards will also give you confidence that the material meets the necessary criteria for durability and performance, ensuring it is fit for the intended application. This thorough evaluation process is vital for making an informed choice that enhances operational efficiency and longevity.

When selecting the best FRP flat plates for industrial applications, budget considerations play a crucial role. It is essential to understand that while cost is a critical factor, it should not be the only determinant. High-quality FRP flat plates may represent a higher initial investment, but their durability, resistance to corrosion, and lower maintenance costs can lead to significant savings over time. Companies should carefully evaluate the long-term benefits of investing in superior materials as opposed to opting for cheaper, lower-quality alternatives that may require frequent replacements.

Additionally, a detailed cost analysis should include not just the purchase price, but also the potential costs tied to installation, ongoing maintenance, and operational efficiency. It's prudent for businesses to assess the total cost of ownership, which encompasses all expenses over the lifespan of the FRP flat plates. Engaging with suppliers to gather accurate quotes and understanding the specific technical specifications needed for your application can help refine budget estimates. Balancing quality and cost will ultimately enable businesses to make a more informed decision, ensuring they choose FRP flat plates that meet their needs without overspending.

When it comes to selecting FRP flat plates for industrial applications, understanding the maintenance requirements and lifespan expectations is crucial. FRP, or fiber-reinforced polymer, is renowned for its durability, but regular maintenance plays a vital role in maximizing its performance. Routine inspections should be conducted to identify any signs of wear or damage, especially in high-stress environments. Simple cleaning protocols can prevent the accumulation of substances that may lead to deterioration. Moreover, applying protective coatings can enhance resistance against environmental elements, extending the service life of the plates.

Typically, the lifespan of FRP flat plates can range from 10 to 30 years, depending on factors such as environmental exposure and load conditions. Understanding these variables helps industries plan for replacements or repairs proactively. When properly maintained, FRP flat plates not only provide exceptional structural integrity but also deliver significant cost savings over time due to their longevity. By prioritizing maintenance and being aware of expected lifespans, businesses can ensure the reliability and efficiency of their FRP solutions in industrial settings.

TradeManager

Skype

VKontakte