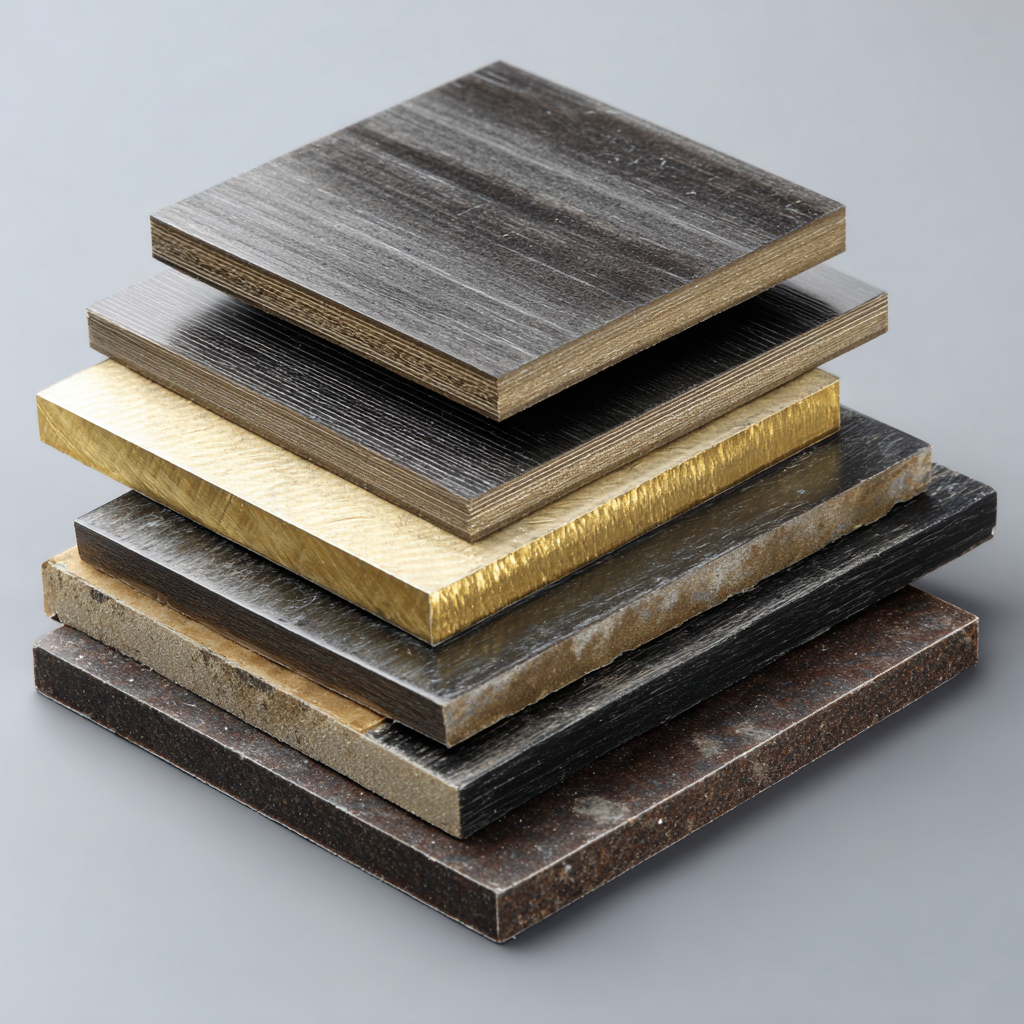

As we approach 2025, the global market for FRP Flat Plates is witnessing significant transformation driven by innovation, sustainability, and advanced manufacturing techniques. This blog aims to explore key trends shaping the landscape of FRP Flat Plates, shedding light on their increasing applications across various industries, including construction, automotive, and renewable energy sectors. With the rising demand for lightweight yet durable materials, FRP Flat Plates are emerging as a preferred choice, seamlessly integrating performance with efficiency. We will also provide valuable tips for stakeholders on how to navigate this evolving market, ensuring they stay ahead of the curve. Join us as we delve into the future of FRP Flat Plates and uncover the opportunities and challenges that lie ahead.

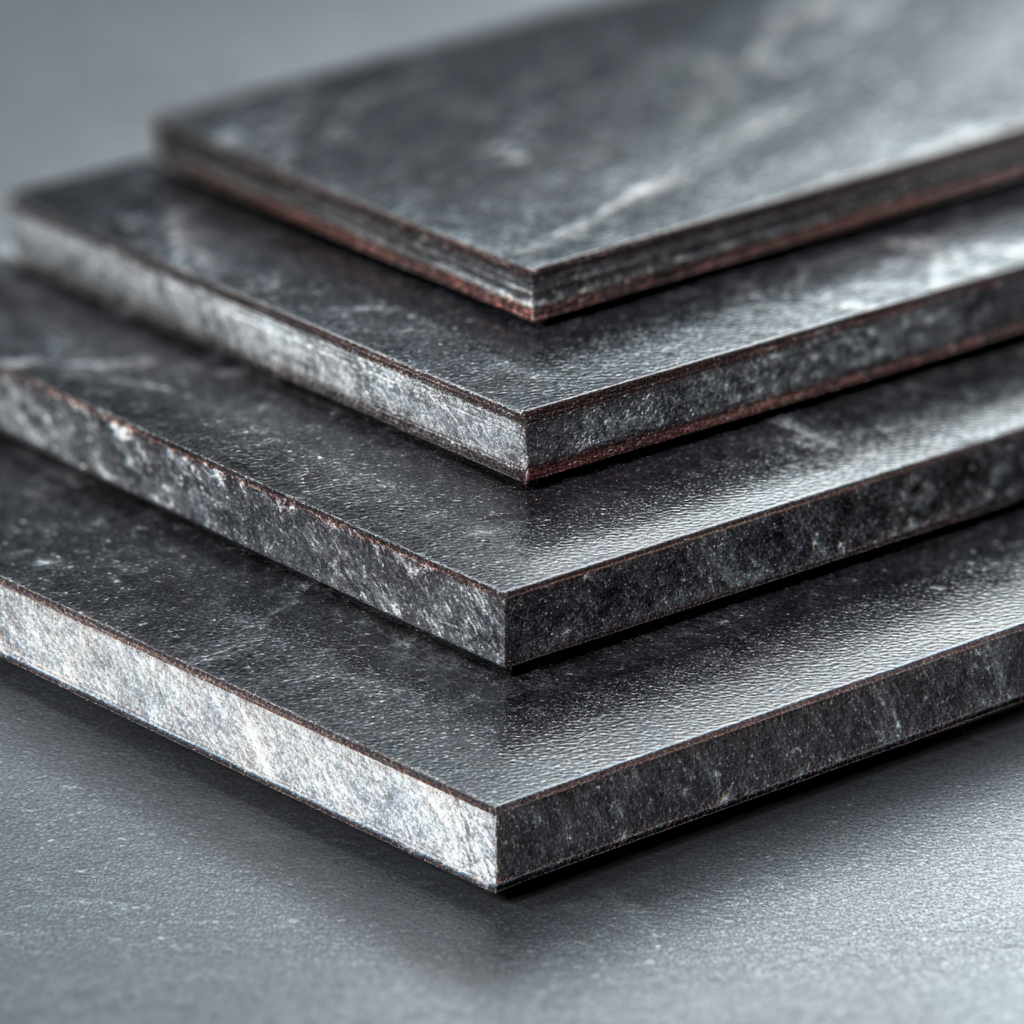

The FRP (Fiber Reinforced Polymer) flat plate market is poised for significant growth by 2025, driven by several key factors. One of the primary drivers is the increasing demand for lightweight and durable construction materials across various industries. As sectors such as automotive, aerospace, and construction prioritize efficiency and sustainability, FRP flat plates offer a compelling solution due to their strength-to-weight ratio and corrosion resistance.

Another notable influence on the market's growth is the rise of renewable energy applications. FRP materials are gaining traction in the manufacturing of wind turbine blades and solar panel mounts, both of which require high-performance materials that can withstand harsh environmental conditions. This trend not only promotes the use of FRP flat plates but also aligns with global sustainability goals.

Tips for businesses looking to tap into this growing market include investing in advanced manufacturing technologies to enhance product quality and reduce production costs. Additionally, staying informed about regulatory changes and sustainability practices in different regions will help in better positioning products to meet market demands. Finally, fostering partnerships with key players in the renewable energy sector can open new avenues for expansion and innovation in the FRP flat plate market.

| Region | Market Size (in Million USD) | Growth Rate (%) | Key Drivers | Challenges |

|---|---|---|---|---|

| North America | 320 | 5.1 | Technological advancement, increasing demand for renewable energy | High material costs |

| Europe | 270 | 4.8 | Regulatory support for renewable energy | Market competition |

| Asia-Pacific | 400 | 6.5 | Rapid industrialization, rising infrastructure projects | Lack of awareness |

| Latin America | 90 | 3.5 | Emerging economies, construction growth | Political instability |

| Middle East & Africa | 130 | 4.2 | Growing investment in renewable energy | Resource availability |

The use of Fiber Reinforced Polymer (FRP) flat plates is witnessing significant growth across various industries, driven by their lightweight nature and superior strength. According to a recent report by MarketsandMarkets, the global FRP composites market is projected to reach USD 20.9 billion by 2025, with a compound annual growth rate (CAGR) of 7.7%. This trend is particularly evident in sectors such as construction, automotive, and aerospace, where the demand for materials that enhance performance while reducing weight is critical.

In the construction sector, FRP flat plates are increasingly employed for their corrosion resistance and load-bearing capabilities, particularly in bridges and high-rise buildings. The Technical University of Denmark has highlighted the efficacy of FRP in retrofitting structures, allowing for lower maintenance costs and increased longevity. Additionally, in the automotive industry, the integration of FRP flat plates is essential to meet stringent regulatory standards for emissions, as they contribute to overall vehicle weight reduction, enhancing fuel efficiency.

The versatility and adaptability of FRP materials make them an attractive choice for emerging applications, positioning them at the forefront of innovation in multiple industrial landscapes.

The demand for FRP (Fiber Reinforced Polymer) flat plates is experiencing a notable surge across various regions, driven by increasing applications in construction, automotive, and aerospace industries. In North America, the trend is leaning towards lightweight and corrosion-resistant materials, which enhances fuel efficiency and sustainability. As regulations tighten around emissions, more manufacturers are adopting FRP flat plates in their designs, resulting in a significant uptick in market growth.

Meanwhile, in Asia-Pacific, particularly in countries like China and India, there is a growing focus on infrastructure development. This region's demand for FRP flat plates is largely influenced by government initiatives aimed at modernizing transport and energy systems. The versatility and durability of these materials cater to both urban and rural development projects, making them a preferred choice for contractors. Additionally, the recent push for renewable energy sources has opened up further opportunities, with FRP flat plates being utilized in wind and solar energy applications due to their excellent weight-to-strength ratio.

The FRP (Fiber Reinforced Polymer) industry is witnessing a transformative wave driven by innovations and technological advancements. As we approach 2025, several cutting-edge technologies are reshaping the production and application of FRP flat plates, making them more efficient and sustainable. One of the most significant trends is the integration of automation in manufacturing processes. Automation not only streamlines production but also enhances the precision and consistency of FRP products. This increase in efficiency is crucial for meeting the rising global demand, particularly in sectors such as construction, automotive, and renewable energy.

Moreover, the use of advanced composite materials is on the rise, reflecting a shift towards lighter yet stronger solutions in various applications. Innovations such as thermoset and thermoplastic composites are opening new avenues for improved performance and durability in challenging environments. Additionally, the development of smart FRP materials, embedded with sensors and monitoring capabilities, is set to revolutionize structural health monitoring. These advancements not only support longer life spans for infrastructure but also contribute to sustainability goals by minimizing waste and enhancing recycling processes. As these trends unfold, the FRP flat plate market is poised for significant growth, driven by a commitment to innovation and environmental responsibility.

The global market for FRP (Fiberglass Reinforced Plastic) flat plates is witnessing significant growth, driven by increasing demand across various industries, including construction, automotive, and aerospace. According to a report by Fortune Business Insights, the FRP composites market is projected to reach USD 41.58 billion by 2027, growing at a CAGR of 6.5%. Leading manufacturers are adopting innovative strategies to enhance their market presence, focusing on product development and strategic partnerships to stay competitive.

For instance, companies like Owens Corning and Hexcel Corporation are investing heavily in R&D to improve the mechanical properties and sustainability of their FRP flat plates. Owens Corning has pioneered advancements in resin systems that enhance durability and resistance to environmental stressors, positioning itself as a leader in high-performance applications. Meanwhile, Hexcel emphasizes the integration of advanced manufacturing techniques, such as automated fiber placement, which not only optimizes production efficiency but also reduces costs. These strategic initiatives reflect a broader trend among industry leaders to leverage technology for better product offerings, catering to the diverse needs of sectors driven by sustainability and composite material innovations.

TradeManager

Skype

VKontakte